The Single Strategy To Use For Turbochargers

Table of ContentsLittle Known Facts About Turbochargers.Facts About Turbochargers RevealedLittle Known Questions About Turbochargers.

Modern turbochargers can utilize wastegates, blow-off valves and variable geometry, as talked about in later areas. In fuel engine turbocharger applications, boost pressure is limited to keep the entire engine system, including the turbocharger, inside its thermal and mechanical style operating variety (turbochargers). Over-boosting an engine frequently causes damage to the engine in a variety of ways including pre-ignition, overheating, and over-stressing the engine's internal hardware.Opening the wastegate enables the excess energy predestined for the turbine to bypass it and pass directly to the exhaust pipeline, hence reducing boost pressure. The wastegate can be either managed by hand (regularly seen in airplane) or by an actuator (in automobile applications, it is frequently controlled by the engine control unit).

The increased temperature level from the greater pressure offers a higher Carnot efficiency. A minimized density of consumption air is triggered by the loss of atmospheric density seen with raised altitudes. Thus, a natural usage of the turbocharger is with airplane engines. As an airplane climbs to greater elevations, the pressure of the surrounding air rapidly falls off.

In airplane engines, turbocharging is typically utilized to maintain manifold pressure as elevation boosts (i. e. to compensate for lower-density air at greater elevations). Since air pressure lowers as the airplane climbs, power drops as a function of altitude in normally aspirated engines. Systems that use a turbocharger to maintain an engine's sea-level power output are called turbo-normalized systems.

5 inHg (100 kPa). Turbocharger lag (turbo lag) is the time required to change power output in response to a throttle change, saw as a doubt or slowed when accelerating as compared to a naturally aspirated engine. This is because of the time needed for the exhaust system and turbocharger to generate the required increase which can likewise be referred to as spooling.

The Facts About Turbochargers Uncovered

Superchargers do not suffer this issue, because the turbine is eliminated due to the compressor being straight powered by the engine. Turbocharger applications can be classified into those that need modifications in output power (such as automotive) and those that do not (such as marine, aircraft, commercial automobile, commercial, engine-generators, and engines).

Engine designs decrease lag in a variety of ways: Lowering the rotational inertia of the turbocharger by utilizing lower radius parts and ceramic and other lighter materials Changing the turbine's element ratio Increasing upper-deck air pressure (compressor discharge) and enhancing wastegate reaction Reducing bearing frictional losses, e. g., utilizing a foil bearing instead of a conventional oil bearing Using variable-nozzle or twin-scroll turbochargers Reducing the volume of the upper-deck piping Using numerous turbochargers sequentially or in parallel Using an antilag system Utilizing a turbocharger spindle valve to increase exhaust gas flow speed to the (twin-scroll) turbine Often turbo lag is misinterpreted for engine speeds that are below boost threshold.

This await lorry speed boost is not turbo lag, it is official statement incorrect equipment selection for increase need. turbochargers. As soon as the car reaches enough speed to supply the needed rpm to reach increase limit, there will be a far much shorter delay while the turbo itself constructs rotational energy and transitions to positive boost, only this tail end of the hold-up in achieving positive increase is the turbo lag.

Listed below a particular rate of flow, a compressor produces irrelevant boost. This limits increase at a here are the findings specific RPM, regardless of exhaust gas pressure. Newer turbocharger and engine advancements have actually progressively reduced increase thresholds. Electrical enhancing (" E-boosting") is a new technology under advancement. It uses an electric motor to bring the turbocharger up to running speed quicker than possible using readily available exhaust gases.

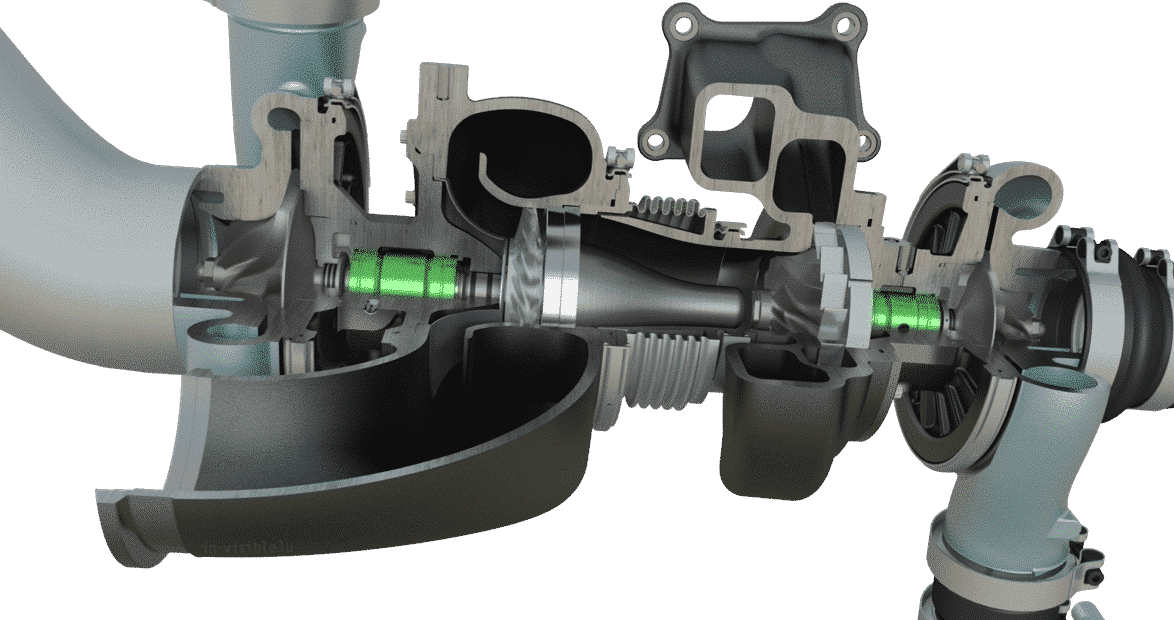

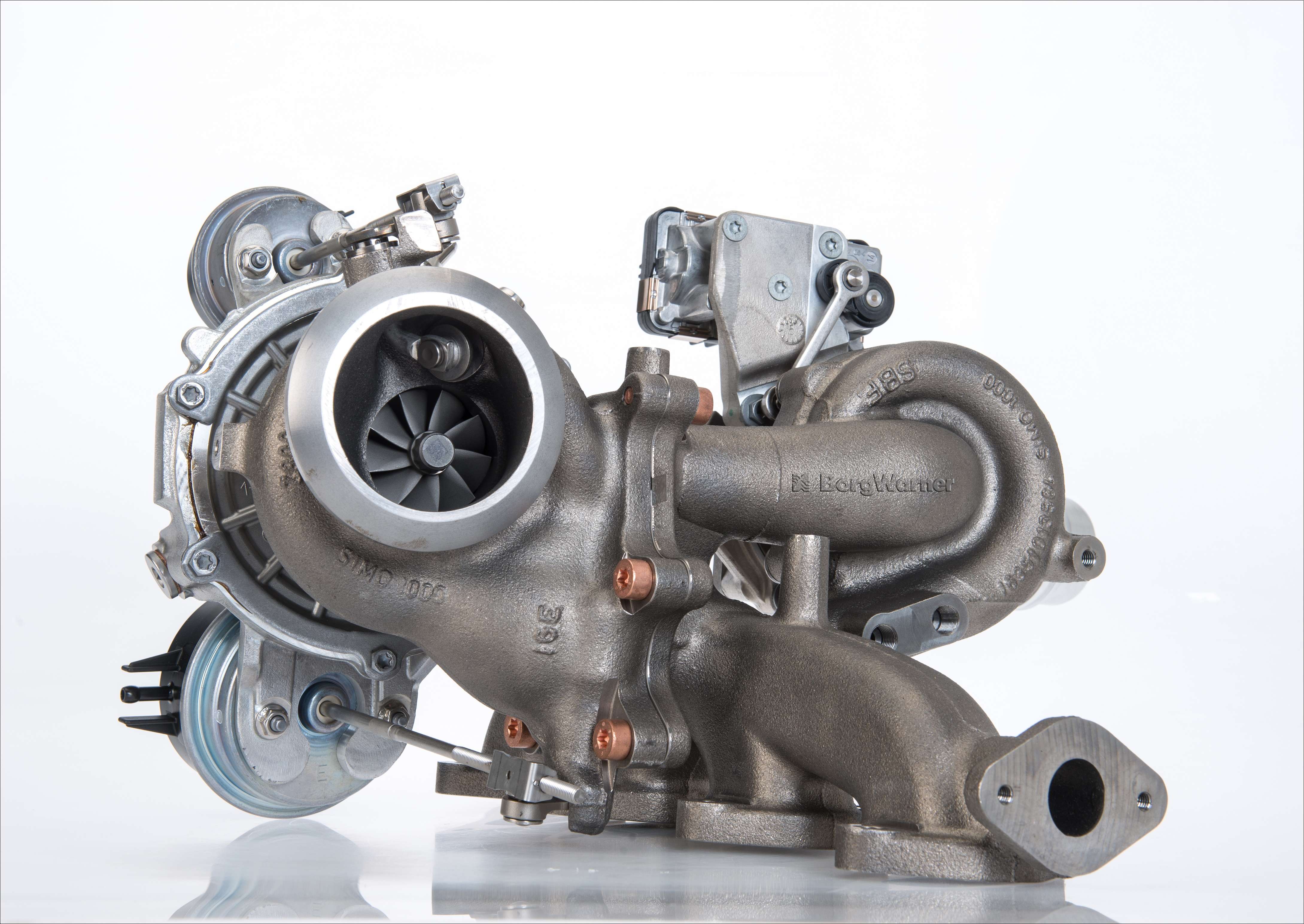

The running speed (rpm) at which there is sufficient exhaust gas momentum to compress the air entering into the engine is called the "increase limit rpm". Lowering the "boost threshold rpm" can enhance throttle reaction - turbochargers. The turbocharger has 3 main parts: The turbine, which is often a radial inflow turbine (however is often a single-stage axial inflow turbine in large Diesel engines) The compressor, which is almost constantly a centrifugal compressor The center housing/hub rotating assembly Many turbocharger setups utilize additional innovations, such as wastegates, intercooling and blow-off valves.

Turbochargers Can Be Fun For Everyone

On the right are the braided oil supply line and water coolant line connections. Compressor impeller side with the cover removed. Turbine side housing removed. Energy offered the turbine work is transformed from the enthalpy and kinetic energy of the gas. The turbine housings direct the gas circulation through the turbine as it spins at up to 250,000 rpm.

Typically the exact same fundamental turbocharger assembly is offered from the producer with multiple housing options for the turbine, and often the compressor cover too. This lets the balance in between performance, reaction, and efficiency be tailored to the application. The turbine and impeller wheel sizes likewise determine the amount of air or exhaust that can flow through the system, and the see this site relative effectiveness at which they run.

Measurements and shapes can differ, along with curvature and number of blades on the wheels. A turbocharger's efficiency is closely tied to its size. Large turbochargers take more heat and pressure to spin the turbine, developing lag at low speed. Small turbochargers spin rapidly, but might not have the very same efficiency at high acceleration.